The cost of a concrete block machine can vary depending on various factors such as the type of machine, its capacity, and features, as well as the manufacturer or supplier. Generally, a small manual machine can cost around $1,000 to $3,000, while a fully automatic machine with a high production capacity can cost upwards of $100,000.

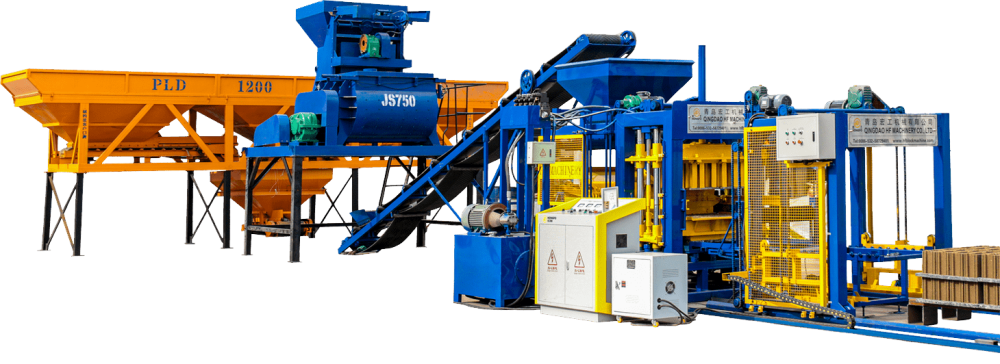

QT6-15 Automatic Block Making Machine

USD $50,000.00-$100,000.00

Pre-sales service - According to local market demands, guide the users to choose the right machine model.Best suggestion for blocks choose.

German and Japanese technology - Siemens brand PLC and Siemens Mortors to be sure machine runs stable and efficient.

Supply A to Z service - for client block business ,24 hours online guiding and local installation service

One year warranty - more spare parts delivery with block machine.

Over 25 Years Lifetime - The life span of our machine is long, can be used over 25 years.

It's important to note that the cost of the machine is just one aspect of the overall investment in a concrete block production business. Other expenses to consider include raw materials, labor, transportation, and marketing.

If you're interested in purchasing a concrete block machine, it's best to research various manufacturers and suppliers to compare prices, features, and customer reviews.

Back To The List

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.