Installation, repair and maintenance of your brick machine steps breakdown:

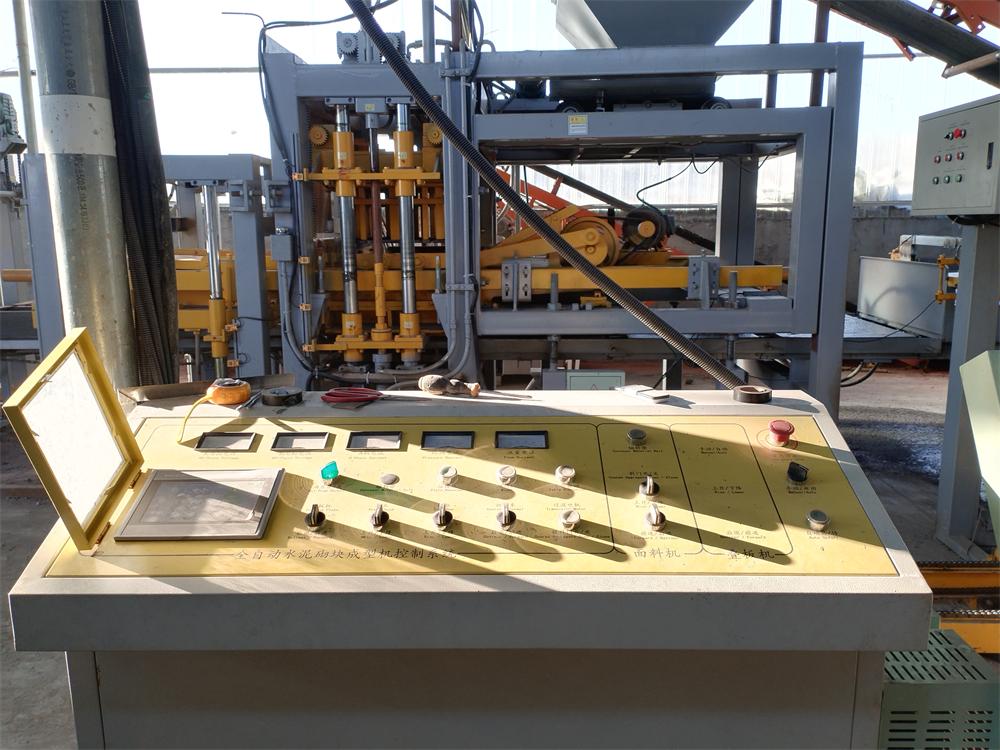

1) Install the brick machine: install according to the instructions and drawings. First of all, choose a stable ground, install the base, install the machine body, connect the power cord and oil pipe, check the tightness of each part, adjust the operating parameters and sensor position, and conduct a trial run after confirming that it is correct.

2) Maintenance of brick machine: Regular inspection and maintenance, and timely replacement or repair of problematic parts. Some wearing parts need to be replaced regularly, such as motor bearings, gears, belts, etc. Regularly clean the dust and residue inside the machine to keep it clean and tidy. If the machine is faulty, check it in time and take appropriate maintenance methods.

3) Maintain the brick machine: The key to maintaining the brick machine is to keep it clean and lubricated. Regularly clean the sundries and stains on the outside and inside of the machine, and replace the lubricating oil and grease in time. At the same time, pay attention to the use of appropriate lubricants and greases to avoid damage to machine parts.

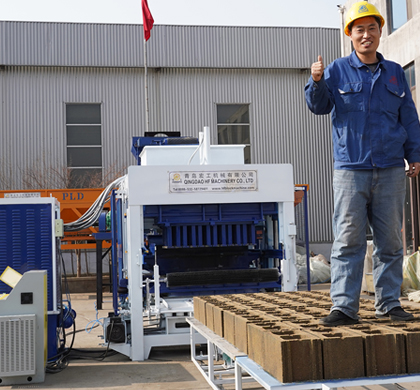

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.