Both hollow blocks and solid blocks have their own advantages and disadvantages, and the choice between them depends on various factors such as the specific application, the cost, and the structural requirements.

Hollow blocks are generally preferred for construction projects because they are lighter and can reduce the overall weight of the structure, which can save on transportation and handling costs. They also provide better insulation and soundproofing, which can help to create a more comfortable living or working environment. Hollow blocks also require less cement and can reduce construction costs.

On the other hand, solid blocks are more durable and can provide better strength and stability to a structure, making them ideal for load-bearing walls and heavy construction. Solid blocks are also less prone to damage from impacts and can provide better fire resistance.

Ultimately, the choice between hollow blocks and solid blocks depends on the specific needs of the project and should be determined by a qualified engineer or architect who can evaluate the structural requirements and make recommendations based on the project specifications.

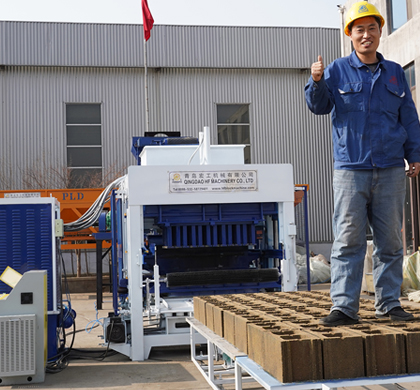

This QT4-25 is the smallest automatic machine, it can adopt PLC to control machine can help customers save labor. Compared with manual, the output is greatly improved, you can see the capacity list per day is 4200pcs per day for 400*200*200mm. It can produce all kinds of hollow bricks, solid bricks and pavement bricks and so on.

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.