T7 block making machine

A. Electricity save: -30% B. Output increase: +20%

C. Maintenance cost: -15% D. Noise reduction: -15%

| Overall Dimension | 13000x7500x3000mm |

| Main vibration form | Platform vibration |

| Cycle Time | 15-25 seconds |

| Pallet Size | 1200x870mm |

| Motors Power | 53.6kw |

| Weight | 9600kg |

| Raw Materials | Crushed stone, sand, cement, dust and coal fly ash, cinder, slag, gangue, gravel, perlite, and other industrial wastes. |

| Applied Products | Concrete blocks, solid/hollow/cellular masonry products, paving stones with or without face mix, garden and landscaping products, slabs, edgers, kerbstones, grass blocks, slope blocks, interlocking blocks, etc. |

| Applied Fields | Widely used in buildings, road pavings, squares, gardens, landscaping, city constructions, etc. |

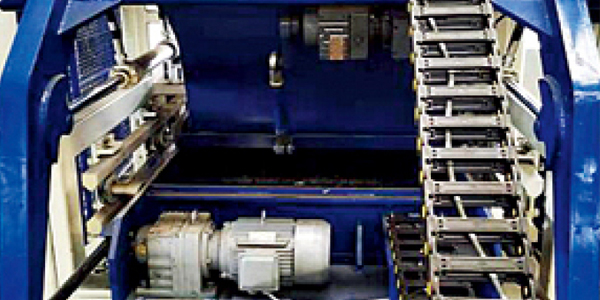

Integrated design of vibrator and vibration platform, combination of dynamic and static platform, penetrating vibration, high vibration frequency, vibrator power part is variable frequency vibration, Siemens variable frequency vibration motor and connecting rod soft connection transmission assembly Direct connection, omitting the belt conveying link in the traditional vibration mode, the vibration speed is faster, the vibration force is stronger, the brick forming speed is decreased by 3-4 seconds, and the output is increased by 20%.

The material feeder adopts 360-degree counter-rotation, and the material is forced to mix twice to achieve fast distribution speed, average material distribution, the forming block is with high product density and uniform height. The bottom plate of the material feeder adopts NM400 high-strength wear-resistant plate, which greatly improves the service life of the equipment. Material hopper is electronically controlled door opening, so the discharge amount can be precisely controlled according to different brick shapes material consumption.

Adopting German frequency conversion technology and frequency control, the host vibration adopts low-frequency standby and high-frequency operation, which improves the operating speed and product quality, while reducing the impact on mechanical components and motors, extending the life of the machinery and motors, achieving 20%~30% power saving than traditional motor operation control.

It adopts German advanced automation control technology and intelligent interactive system to realize real-time operation and man-machine dialogue, making easier operation control, greatly saving the labor costs and decreasing the failure rate to ensure stable operation condition, it also has product formula management and operation data collection functions.

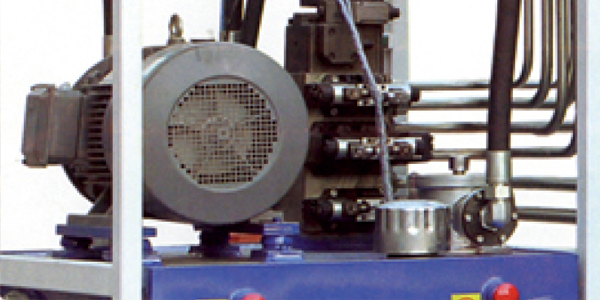

The main motor of the hydraulic station adopts Siemens motor, the main oil pump, double proportional valve, and solenoid valve are all of Japan Yuken brand, with stable performance, low failure rate, advanced design, reasonable structure, and fast and stable operation of each action. The tubing adopts imported Italian tubing, which is resistant to aging and does not leak oil and has a long service life. The trapezoidal design of the tubing is neatly arranged and has a reasonable trend.

| Block type | Image | Size (mm) L*W*H | Molding cycle | QTY (pcs)/Mould | Qty(pcs)/hour | Qty(pcs)/8hr |

| Hollow block |  | 400x200x200 | 14-20 | 7 | 1260-1800 | 10080-14400 |

| Solid block |  | 240x115x53 | 14-20 | 44 | 7920-11314 | 63360-90512 |

| Paver |  | 225x112.5x60 | 14-20 | 20 | 3600-5142 | 28800-41136 |

| Paver |  | 200x100x60 | 14-20 | 30 | 5400-7714 | 43200-61712 |

Ground Block Series1

Ground Block Series1

Ground Block Series1

Ground Block Series1

Ground Block Series1

Hollow Block Series1

Hollow Block Series1

Hollow Block Series1

Hollow Block Series1

Hollow Block Series1

Product Application1

Product Application1

Product Application1

Product Application1

Product Application1

If you have any questions, please leave a message, we will reply as soon as possible.

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.