Global Cases

The building materials industry is a booming industry with a variety of prospects. It is also one of the most important sectors in the construction industry. The building materials industry has been on an upward trend in recent years, and it is expected t

A block-making machine is what cuts and forms blocks of material, such as stone or concrete, into shapes. Block-making machines are used in construction to make the building blocks for buildings. They are also used to make paving blocks and curbstone.

There are many reasons why you might want to buy a second hand machine. You may have just started your own business and need an additional machine or you may have had an accident with your current machine and need a replacement.

A loader pours some raw materials (rubble, stone, sand, limestone, metal tailing, fly ash or solid construction waste) into the aggregate hopper. There’s an aggregate weighing batcher (under the hopper) weighing the materials accurately and automatically.

You need to have a large space not only for production and drying your blocks but also for storing raw materials. Make sure the land is not a swampy area because it will be affecting the dryness of your blocks as the humidity prevent blocks from dryness.

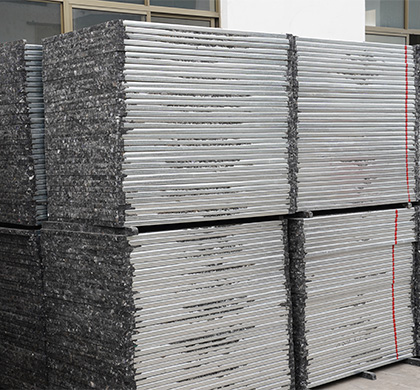

When producing concrete blocks by cement brick making machine, it is very important to choose good pallets for support and stack the finished wet blocks. In this industry, the optional pallets for concrete block machines are wooden pallets, bamboo pallets

Identifying The Quality of Block Making Machine Equipment

Paver block making machine is a kind of equipment that is used for making paver blocks. It can be divided into two categories, namely, dry process and wet process. Dry process is the traditional way for producing paver blocks, but it has some disadvantage

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

Gemini Tower, Block B, Chunyang Road, Chengyang District, Qingdao, China

Show on the Map

We will contact you within 24 hours.