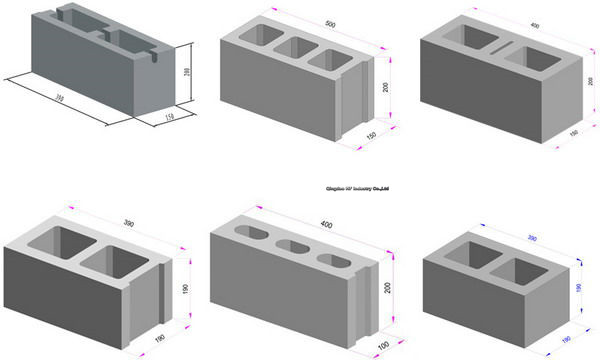

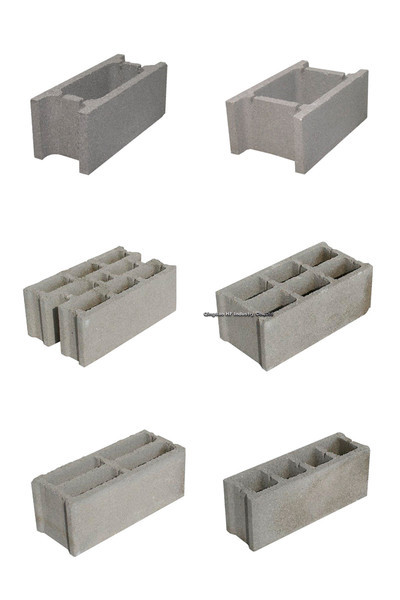

Hollow blocks, also known as concrete masonry units (CMUs) or concrete blocks, are commonly used in construction for various purposes. These blocks are made from concrete or cement and have hollow cavities, which provide several advantages in construction. Here are some common uses for hollow blocks:

Load-Bearing Walls: Hollow blocks are often used to build load-bearing walls in buildings. Hollow blocks are used to construct walls in both residential and commercial buildings. They provide structural support and help in creating sturdy and durable walls. The hollow cavities reduce the overall weight of the block while still providing strength and stability. These walls can support the structure of a building and resist vertical loads.

Partition Walls: Hollow blocks can be used to create partition walls within a building. These walls separate different spaces or rooms and do not necessarily need to bear significant loads. Their lightweight nature makes them a cost-effective choice for this purpose.

Exterior Walls: In some construction projects, especially in regions with hot or humid climates, hollow blocks are used for exterior walls. They provide good thermal insulation, which can help regulate the temperature inside a building. Additionally, the cavities can be filled with insulation materials to enhance energy efficiency.

Retaining Walls: Hollow blocks are used in the construction of retaining walls, which are designed to hold back soil or other materials. The hollow design allows for drainage and reinforcement options, making them suitable for this purpose.

Soundproofing: Hollow blocks can be used to create soundproof walls. By filling the cavities with sound-absorbing materials, they can effectively reduce noise transmission between rooms or from external sources.

Facades: In architectural applications, hollow blocks are sometimes used to create decorative facades. Their texture and visual appeal make them a choice for adding an aesthetic element to a building's exterior.

Pavers: Some hollow blocks are designed as interlocking pavers for creating walkways, driveways, or other outdoor surfaces. These blocks are durable and allow for easy installation.

Fire Resistance: Hollow blocks can provide fire resistance when filled with fire-resistant materials. This is especially important in certain building codes and applications where fire safety is a priority.

The specific use of hollow blocks depends on the construction project's requirements and the type of hollow blocks being used. They are versatile and widely used in the construction industry due to their affordability, strength, and adaptability to various construction needs.

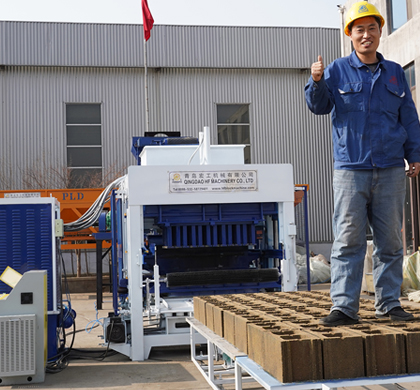

QT5-15 automatic concrete cement block making machine is our core competence block machine, it is full automatic can make all types of hollow blocks, solid blocks, pavers, curbstones and so on. it adopts our most advanced hydraulic system and vibration system, can ensure the block quality very good and the working noise very low. We cooperated with SIEMENS, SCHNEIDER, OMRON, CALYCA and so on to make sure our block machine with high quality and keep our machine work more stable.

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.