1. Optimizing the ratio of ingredients: the quality of concrete bricks is affected by the ratio of raw materials. By adjusting the ratio of raw materials such as cement, sand, and stones, the strength, durability, and other performance indicators of concrete bricks can be improved, thereby improving the quality of the bricks.

2. Use of high-quality raw materials: the use of high-quality cement, sand, stones and other raw materials can significantly improve the quality and strength of concrete bricks. High-quality raw materials that meet national standards should be selected, and contamination and impurities should be avoided during storage, handling and use.

3. Optimizing the production process: The production process also has an important impact on the quality and output of concrete bricks. Advanced technologies such as automation and assembly line production can be used to improve production efficiency and consistency; and through scientific process control such as pouring, compaction, and maintenance, the compactness and durability of concrete bricks can be improved.

4. Maintenance of equipment and machines: Keeping production equipment and machines in good condition is also crucial to improving the output and quality of concrete bricks. Carry out regular maintenance and overhaul, and replace worn or damaged parts in time to ensure the normal operation and production efficiency of the equipment.

5. Increase input and manpower: Increase the input of raw materials and labor, which can increase the output of concrete bricks. At the same time, increasing the training and experience accumulation of skilled workers can also improve the quality and production efficiency of concrete bricks.

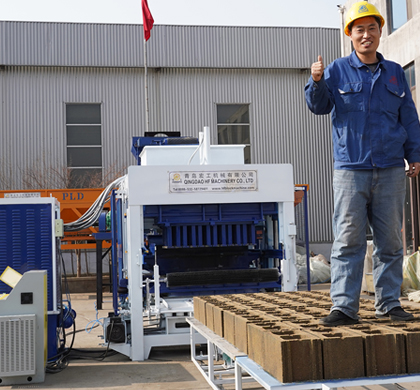

Block machines play a crucial role in modern construction, facilitating the production of various types of blocks used in buildings, roads, and infrastructure projects. To ensure optimal efficiency and longevity of these machines, it's essential to unders

There are several types of block machines used in various industries for producing different types of blocks, such as concrete blocks, cement blocks, and interlocking blocks. Some common types include:

The first step in maximizing the potential of a brick making machine is to select the right machine for the job. Consider factors such as the size of the bricks you need to produce, the production capacity required, and the specific features and capabilit

Whether for inquiries for inspections and

maintenance, for individual plant optimizations or

extensions, or spare and wear parts.

Our after-sales service is at your disposal for all

questions

We will contact you within 24 hours.